Jet utilizes state-of-the-art technology to provide laser-cut parts with exceptional accuracy, regardless of the complexity of the geometry. With the ability to cut a wide range of metal types and thicknesses we can meet your specific requirements with efficiency and precision.

Our advanced turret punch presses are capable of providing punched as well as formed features, accommodating thin sheets to thicker plates. With our skilled operators and versatile capabilities, we can deliver high-quality punched parts accurately, repeatably, and with quick turnaround times.

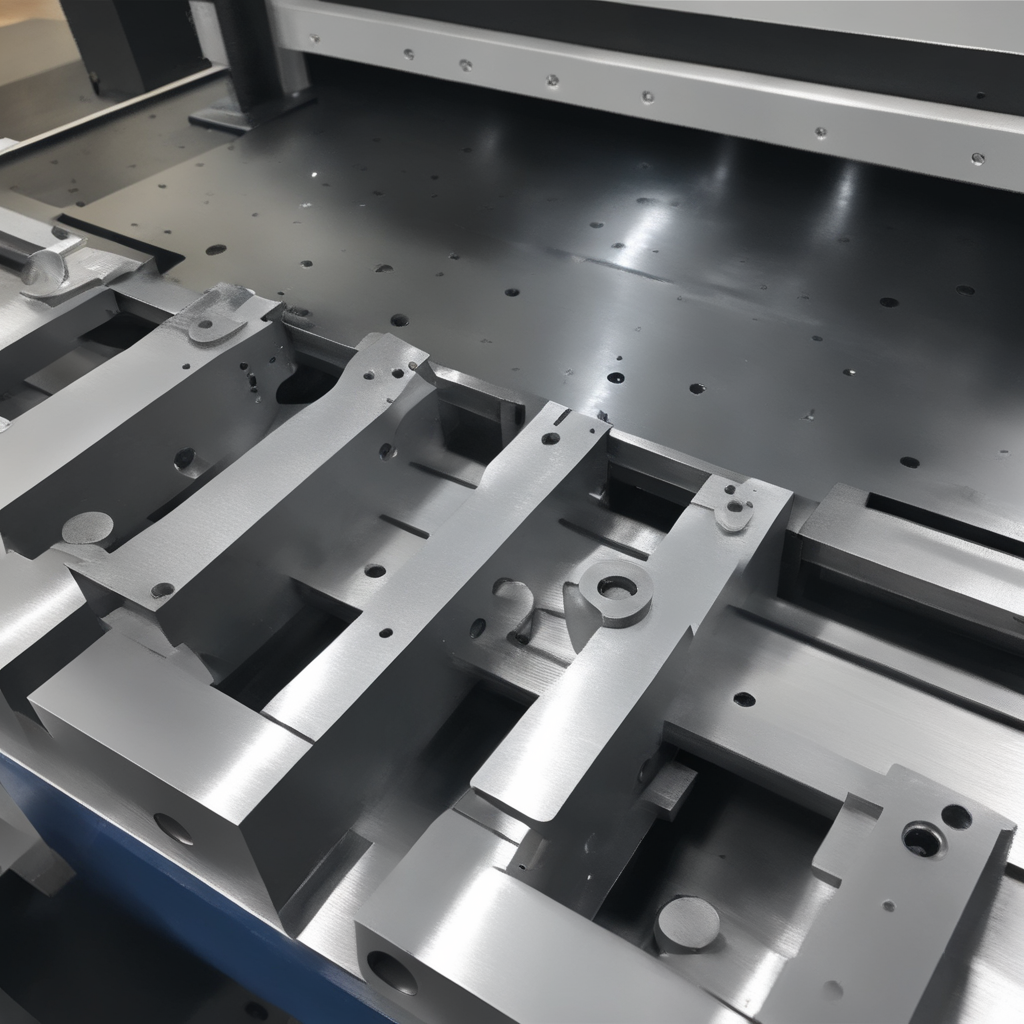

Jet’s Machining department is equipped with world-class, cutting-edge capabilities which include 3, 4, and 5-axis milling and turning centers. Our machining centers boast 3D surfacing as well as high and super-speed capabilities. We are adept at handling a wide range of materials including but not limited to aluminum, steel, stainless steel, and many plastics. The result is a winning combination that enables us to offer our customers exceptional accuracy, flexibility, and quality from prototype to large-scale production.

Often the most critical part of a sheet metal component or assembly, sheet metal forming is accomplished at Jet by way of highly skilled and experienced operators utilizing modern bending equipment. We can produce intricately bent parts with a high degree of accuracy and repeatability and are adept at ensuring that mating components function together seamlessly.

At Jet Precision Metal we offer value-added assembly services ranging from small-scale hardware insertion to large-scale project management featuring complex assembly of numerous components. Our high level of expertise coupled with meticulous attention to detail and rigorous quality control ensure reliable and accurate products.

Jet utilizes industry-leading spotwelding equipment to provide results that are second to none. Working with a wide range of material types and thicknesses, we can produce spot welded components you can depend on for strength and reliability. Our experienced operators can help solve complex applications with care and precision.

Your products aren’t complete until they’ve passed through our sanding and polishing department where our skilled craftsmen employ their knowledge and talents to provide an array of finishes. Whether you require a sanded finish, a smooth polish, or a textured surface, our team will work with you to achieve the surface finish that satisfies your specific functional or cosmetic needs.

Our welding capabilities encompass MIG, TIG, and Laser welding techniques, ensuring versatility for various applications. Our team of highly skilled welders holds AWS (American Welding Society) certification, demonstrating their commitment to quality and craftsmanship. With their expertise, we excel in producing welded components that meet the highest industry standards.

By leveraging these diverse capabilities, Jet Precision Metal is dedicated to delivering top-quality manufacturing solutions that cater to your specific requirements

7 Schoon Avenue

Hawthorne, New Jersey 07506